Integrity Operating Windows (IOW)

What are Integrity Operating Windows?

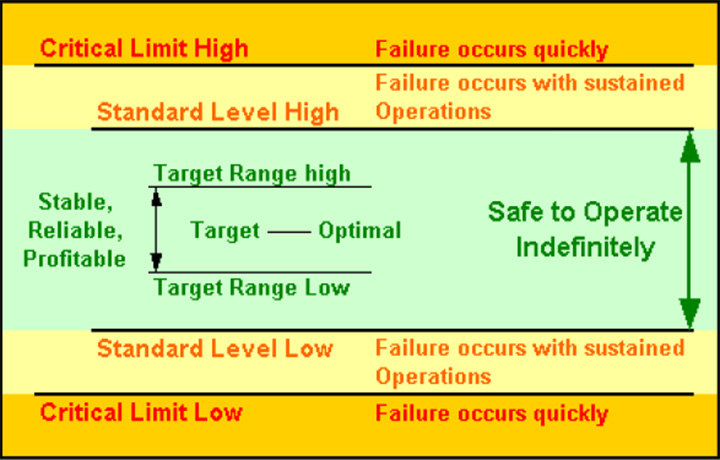

Integrity Operating Windows (IOW) are a key component of Corrosion Control Documents. As part of an effective mechanical integrity program, IOWs are sets of limits used to determine the different variables that could affect the mechanical integrity and reliability of a process unit. Working outside of IOWs may cause otherwise preventable damage or failure.

“… a typical RBI assessment program is particularly ineffective in reducing risk … in the absence of expert input.”

The American Petroleum Institute (API) has a new Recommended Practice (API RP 584) that describes the importance of establishing and monitoring limits to control process variables that could affect the integrity or reliability of process unit equipment. They are particularly useful for capturing in one document, the essential parameters of a chemical or refining process that influence corrosion and other damage mechanisms, i.e. materials of construction, process-stream chemistry, pH, corrosion rates, contaminants, operating temperature, and pressure. An example of an Integrity Operating Windows (IOW) is the establishment of furnace tube temperature limits to avoid premature rupture. At some established limit, say 800℉, a furnace tube designed for 775℉ would have a shortened service life, so operators would understand the need to maintain control of furnace firing to remain below the 775℉ limit. That limit of 775℉ would be an IOW limit for the furnace tubes.

The Hendrix Group has developed Corrosion-Control Documents and Integrity Operating Windows for the following processes:

- Diesel Hydrotreater units (DHT)

- Naphtha Hydrotreater units (NHT)

- FCC Naphtha Hydrotreater (CDTECH)

- CBI/Lummus Delayed Coker

- Saturation gas units (SAT)

- Gasoline Stabilization Units

- Natural gas plants

- Fluid Catalytic Cracking units (FCC)

- Gas Concentration Units (GCU)

- Merox units

- Mericham NAPFINING unit

- Sulfur Recovery Units (SRU)

- Sour Water Stripper units (SWS)

- Syngas/PSA Hydrogen units

- CO boiler

- Amine units

- Methanol unit

- Acetic acid unit

- Vinyl acetate monomer unit

Related Engineering Services