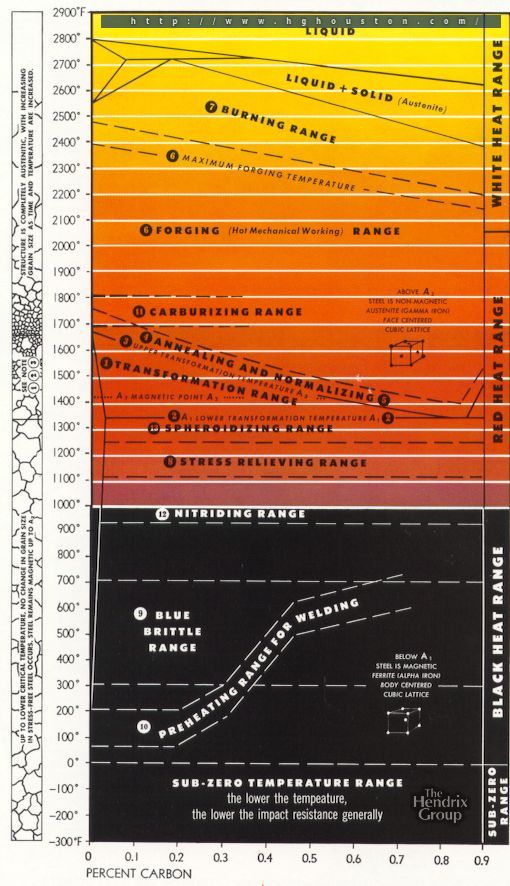

(Notes below correspond to numbers in the chart)

1. Transformation Range - In this range steels undergo internal atomic changes which affect the properties of the material.

2. Lower Transformation Temperature - (AC1) Temperature at which structure begins to change from ferrite and pearlite to austenite if being heated, upon cooling, temperature at which structure completes change from austenite to ferrite and pearlite.

3. Upper Transformation Temperature - (AC3) Temperature at which structure completes change from ferrite and pearlite to austenite if being heated, upon cooling, temperature at which structure begins change from austenite to ferrite and pearlite.

4. Annealing - Heating steels to slightly above AC3 , holding for austenite to form, then slowly cooling (usually in a furnace) to produce ferrite and pearlite with a small grain size, softness, and good ductility.

5. Normalizing - Heating to slightly above AC3 , holding for austenite to form, then slowly cooling in still air (usually out of the furnace) to produce material with somewhat higher strength, hardness and less ductility than that produced by annealing.

6. Forging Range - Usually conducted several hundred degrees above AC3. Typically in the range of 1800F to 2000F.

7. Burning Range - Results in steels that have to be remelted due to liquation and other problems.

8. Stress Relieving - Heating to below AC1 and holding sufficiently long to relieve internal stresses and then slowly cooling.

9. Blue Brittle Range - Loss of ductility while at temperatures from approximately 300F to 700F compared with temperature ranges above and below this range.

10. Preheating for Welding - Recommended temperature range for preheating steels and alloys to precent cracking while welding. Temperature increases with the carbon content.

11. Carburizing - Temperatures normally used to carburize steels (dissolving carbon into the surface of steels using high carbon gaseous atmospheres.)

12. Nitriding - Temperatures normally used to nitride steels (dissolving nitrogen into steels, usually with an ammonia-based atmosphere).

13. Spherodizing - Heating to just below AC1 sufficiently long for for the cementite constituent of pearlite to change into globular form. May take many hours to complete.

Map provided by Tempil, makers of temperature indicating devices.

Map provided by Tempil, makers of temperature indicating devices.